Topology Optimization advancement is a kind of generative plan that joins three disciplines – plan, reproduction, and improvement – to build a reenactment that considers great many huge number of levels of opportunity to track down the best arrangement.

Topology Optimization enhancement permits specialists to find some kind of harmony among strength and cost. It achieves so such that would be difficult to achieve without the help of a PC. This can incidentally bring about odd shapes, which is the reason geography improvement and added substance fabricating remain closely connected; 3d metal printing and plastic 3d printing is the best innovation for making these mind boggling parts.

Rapid prototyping empowers organizations to change over exceptional thoughts into business items in record time. Figure out how 3D printing empowers this.

Unbelievable AM works together with a huge group of profoundly qualified and experienced pioneers, designers to rejuvenate the thought. Our best in class office has each of the vital conveniences to give the best potential answers for ventures at the least conceivable expense, with the best conceivable quality, and the most brief conceivable lead time.

Topology Optimization shape streamlining can make complex designs that have the best solidness to weight proportion while utilizing least material. They might be produce involving add substance as well as subtractive assembling processes.

AM gives a lot of opportunity to the fashioner yet where level items are concerned, progressed subtractive assembling strategies can make leaves behind complex calculation similarly as successfully.

Every technique will force different assembling limitations on topology optimization and math of components and how the creation cycle will go about with its creation.

Upgrading parts through geography enhancement without applying producing requirements will bring about natural looking plans (see picture on the left). This is on the grounds that the material will pick the briefest way from the heap to the requirement, bringing about the most effective shape numerically. Natural outcomes give a decent comprehension of the practical necessities of the part.

A few astounding techniques that can fabricate these imaginative arrangements are:

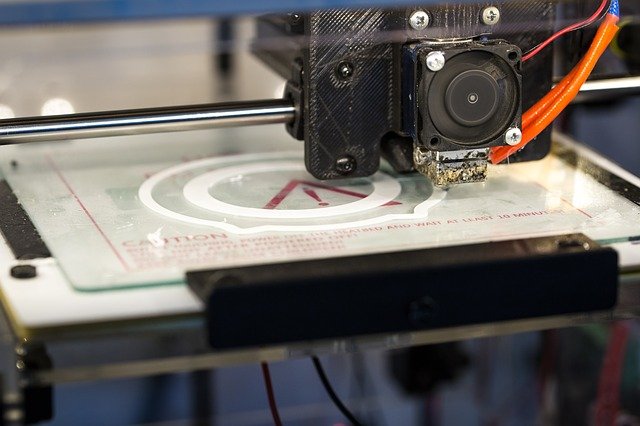

3D printing

3D printing has been instrumental in carrying geography improvement to the spotlight. Without added substance processes, it is almost difficult to make the intricate constructions planned by numerous other streamlining strategies, particularly generative plan, notwithstanding TO.

3D printing offers a quick and proficient method for making topologically enhanced items with practically no wastage. There are many benefits to 3D printing and not very many restrictions. Among the constraints of 3D printing is that main a small bunch of metals can be utilize with it as it was initially intends for plastics.

CNC machining

As the utilization of TO became broad. Endeavors is makes to add elements to PC programs that permit customary creation techniques to make these parts.

As TO makes empty designs with help constructions of non-uniform thickness, it is hard to utilize CNC machining for perplexing parts. However, for models where the visual limit covers with Vmap (Visibility map) totally, the part is manufacturable with CNC.

Perceivability is an idea characterize underway to comprehend the limit of a specific interaction to make a specific part. In commonsense cycles, a section is supposed to be noticeable on the off chance that no focuses on. Its surface are stowed away from the interaction headings. Obviously, a 5-pivot CNC machine will actually want to make results of more prominent trouble than a 3-hub CNC machine.

Laser cutting

Laser machining can likewise function as a creation cycle for TO items. This strategy is fit for cutting unpredictable shapes with lucky precision.

Laser cutting can be utilize on a few distinct materials (metals, wood, acrylic, MDF) making it more helpful while subtractive assembling is feasible for a TO part.